Stop Guessing. Start Knowing: Smart, Data-Driven Facility Care You Can Trust.

Most cleaning companies still rely on clipboards, paper logs, and hope. That leaves you guessing if critical areas are actually being maintained. With Millennium SmartClean, you get real-time data that proves the job is done right every time. Our technology removes the guesswork, so you have complete confidence in your facility’s cleanliness.

Your operations can’t afford to guess if critical areas are being maintained. Now, you’ll always know.

What is Millennium SmartClean?

Millennium SmartClean takes the uncertainty out of facility care. Instead of wondering if your cleaning program is being followed, you get real-time proof. Powered by Mero technology, SmartClean uses IoT sensors and live data to track, validate, and optimize every step of the process. That means no more guesswork just consistent, measurable results you can trust.

Unlike traditional janitorial services that rely on manual checklists and supervisor spot-checks, SmartClean provides continuous validation that critical areas receive proper attention, with scientific documentation you can access anytime

Finally, Cleaning You Can Prove - Not Just Promise

- Automated Cleaning Validation with Documented Proof

- Know in Real Time Bluetooth-powered tracking shows you exactly when and where cleaning happens, so there’s no second-guessing.

- Reduce Risk, Protect Your Team Automatically capture cleaning records that demonstrate accountability protecting your employees, guests, and your business from unnecessary risk.

- Get Proof of Service Every action is logged with time, date, and location giving you complete visibility and peace of mind.

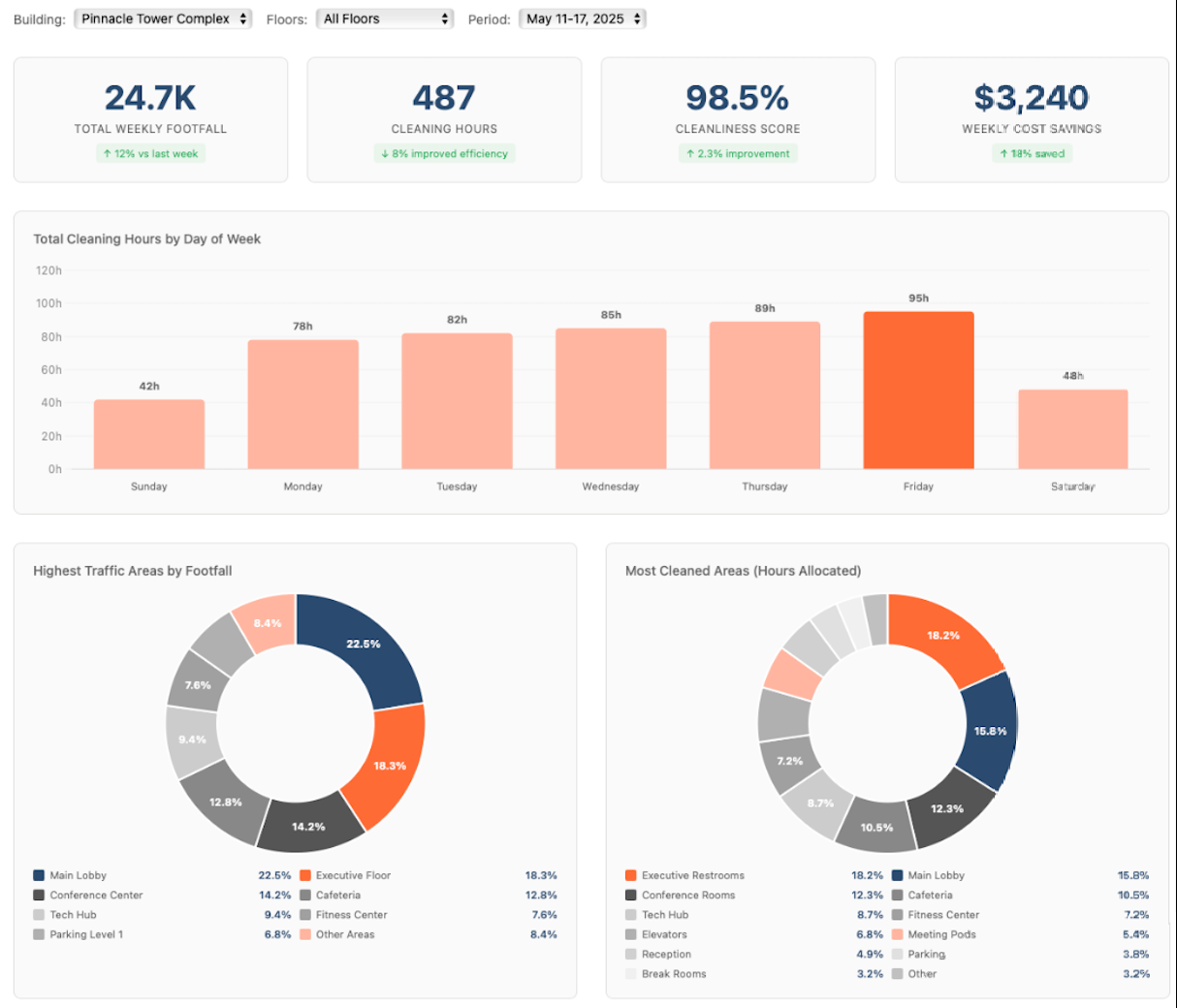

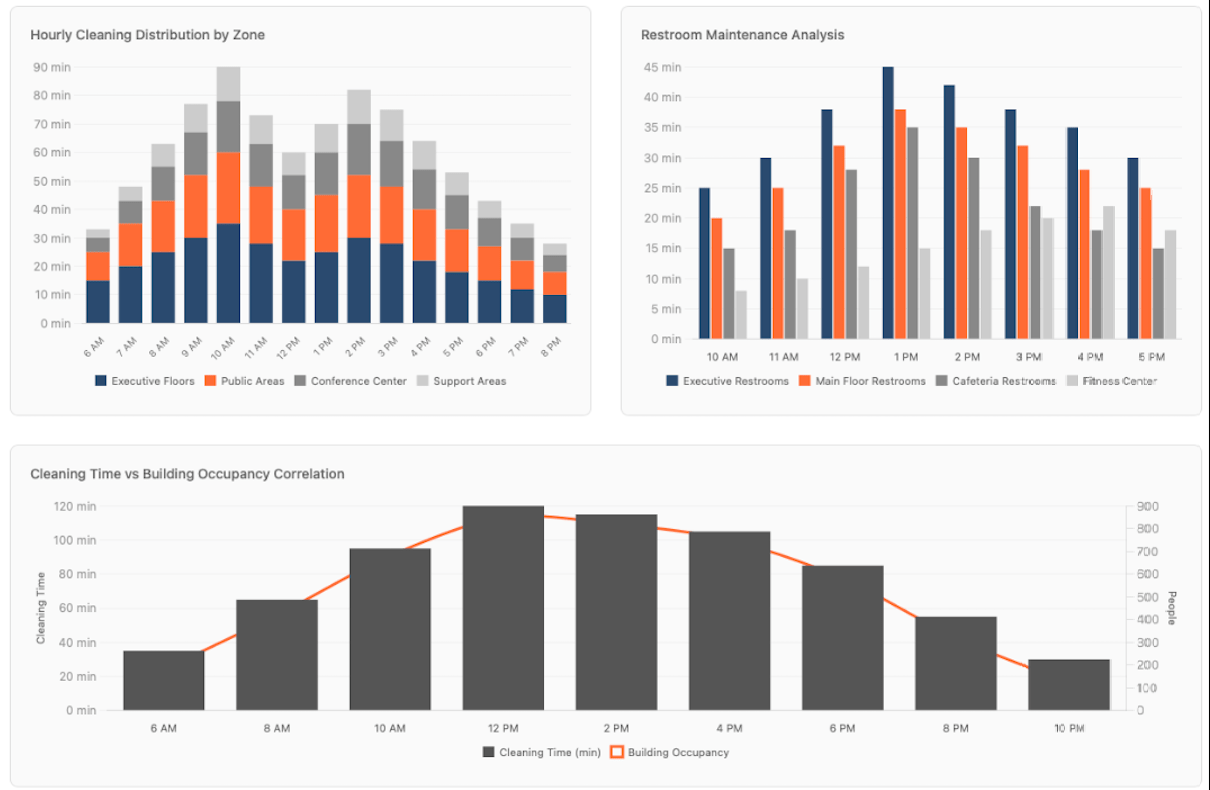

- Turn Cleaning Data into Confident Decisions

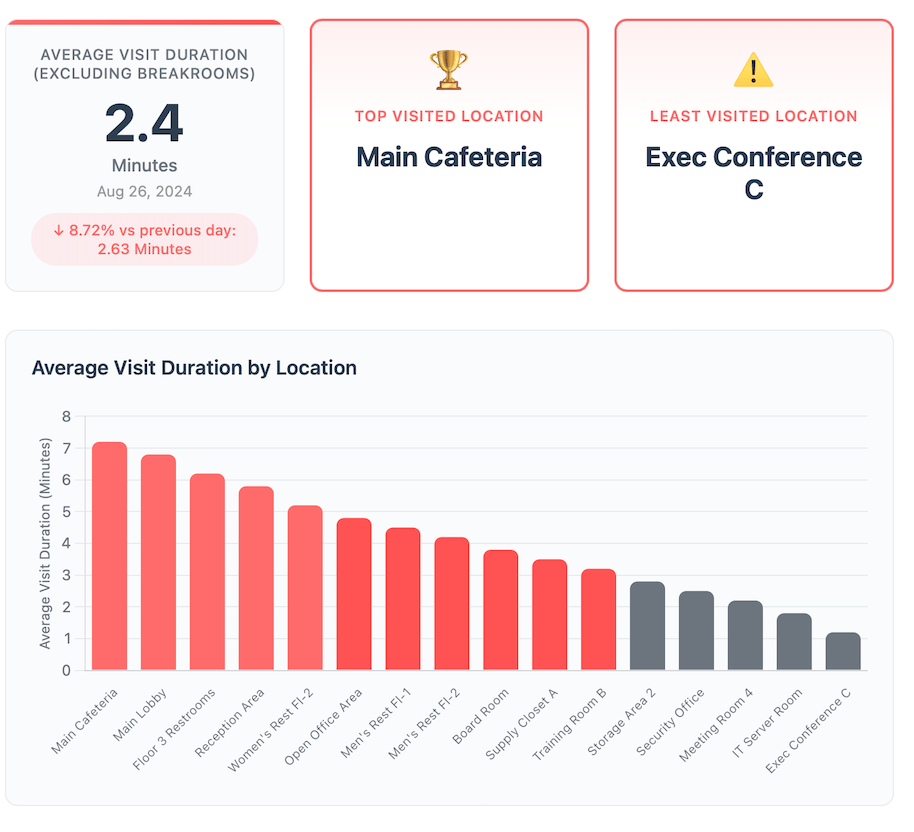

- See What’s Really Happening Access real-time data on task completion, occupancy, and supply usage so you know exactly where attention is needed suply usage for informed decision making.

- Reports That Speak Your Language From resource planning to executive updates, SmartClean delivers custom reports that give your team clarity without complexity.

- Spot Problems Before They Grow Identify usage trends and emerging issues early, so you can prevent costly breakdowns and keep operations running smoothly.

- Clean Smarter, Not Harder: Optimize Resources with Real Usage Data

- Right People, Right Place, Right Time Stop wasting labor on areas that don’t need it. SmartClean adjusts cleaning schedules based on real usage, so your team is always focused where it matters most.

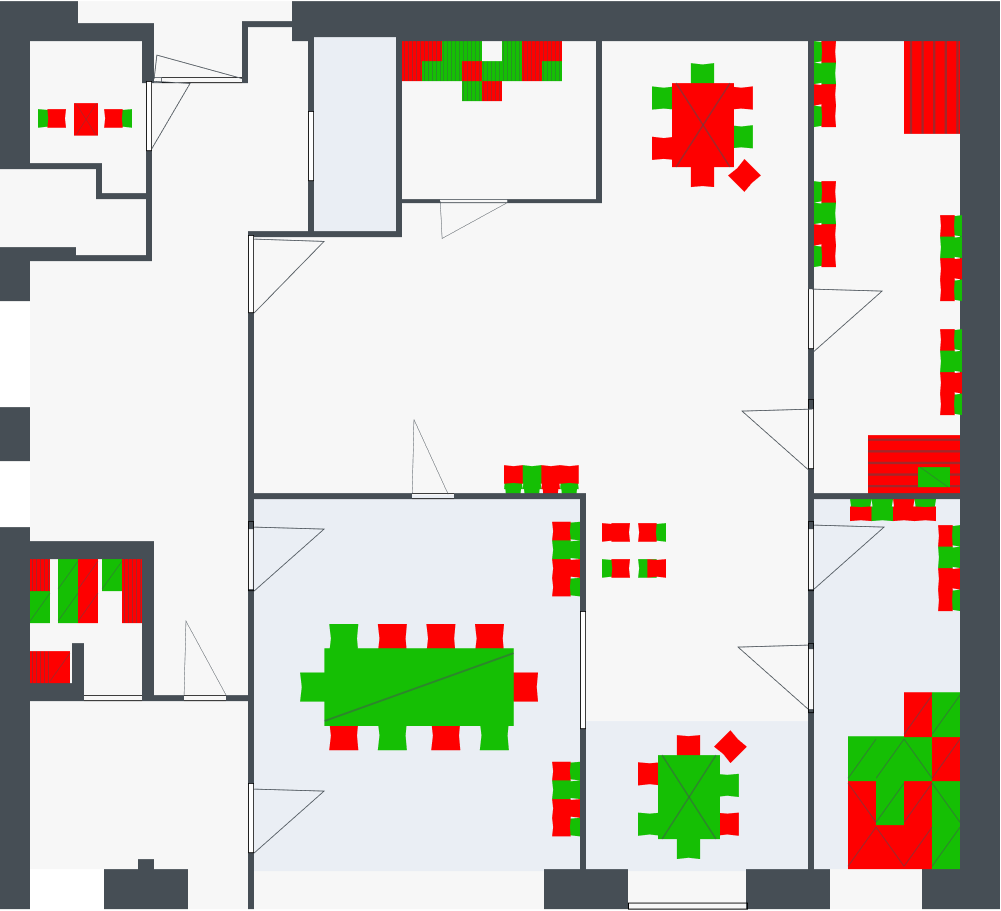

- See the Hot Spots Before They Become Problems Heat maps reveal your highest traffic areas, helping you prevent wear, maintain safety, and allocate resources with precision.

- Cleaning That Never Gets in the Way Your team shouldn’t have to work around cleaning crews. With SmartClean, maintenance happens seamlessly in the background aligned to your schedule so you avoid disruptions, keep everyone focused, and maximize productivity.

- Never Run Out of the Supplies You Need

- Real-Time Inventory Tracking Stop running out of critical supplies. Get instant alerts when stock is low so your team is always ready.

- Smart Replenishment Avoid waste and guesswork. Our system predicts when to reorder so you only buy what you need.

- Seamless Integration Easily connect with your current procurement systems for smooth, automated supply management.

SmartClean Technology Platform

Sensors That Never Let You Down

- Sensors built to perform in tough environments always reliable.

- Works without WiFi, so coverage isn’t a problem in large spaces.

- Built-in security keeps your operational data safe.

- Long-lasting batteries (3+ years) mean less maintenance and fewer interruptions.

A Dashboard Anyone Can Use

- See your facility’s status in real time, from anywhere.

- Mobile-first design makes managing on the go easy.

- Simple interface no special training needed for your staff.

- Customizable alerts ensure you’re only notified when it matters.

Integrations That Fit Your World

- Connect seamlessly with 300+ business applications you already use.

- API access allows custom workflows tailored to your operations.

- Works with your existing CMMS and EAM systems no rip-and-replace.

- Scales effortlessly, whether you manage one site or dozens.

Commercial Properties

- Elevate Tenant Experience Show tenants and employees that cleanliness is consistent, reliable, and visible no more complaints about missed areas.

- Boost Retention & Reputation A clean, safe environment builds trust with tenants and makes properties more attractive to future occupants.

-

Protect People from Hazards Reduce slips, trips, and contamination risks with proactive floor care and real-time validation.

Improves worker safety by ensuring proper floor care and hazard removal - Simplify Oversight Give property managers clear, documented proof of cleaning so they can focus on running the property not chasing cleaning issues.

Education Facilities

- Healthy Learning Environments Consistent cleaning ensures classrooms, cafeterias, and common areas remain safe for students and staff.

- Compliance with Standards Meet state and district health requirements with documented, verifiable cleaning protocols.

- Minimize Classroom Disruptions Schedule cleaning around school hours, activities, and events to avoid interrupting learning.

- Protect Students and Staff Reduce the spread of germs and improve overall well-being with proactive, high-touch surface sanitation.

Medical Facilites

- Protect Patients & Families Maintain the highest level of cleanliness in waiting rooms, patient areas, and common spaces to reduce risks of infection.

- Support Caregivers Give medical staff confidence that sanitation is consistent, so they can focus fully on patient care.

- Build Trust Through Transparency Provide real-time proof of cleaning to reassure patients and their families.

- Reduce Risks Proactively Identify high-traffic areas early and prevent issues before they become safety concerns.

Manufacturing Facilities

- No Shift Left Behind Cleaning aligned with production schedules ensures 1st, 2nd, and 3rd shifts all return to a clean, safe environment.

- Minimize Contamination Risks Focus cleaning where traffic and material handling are heaviest to protect product quality and compliance.

- Protect Workers on the Floor Reduce slips, trips, and hazards with consistent floor care and hazard removal.

- Keep Production Moving Cleaning happens around shift changes and breaks, so sanitation never disrupts operations.

Distribution Centers

- Keep Goods Moving Floors stay clean and safe so your teams can focus on shipping and receiving not slipping hazards or slowdowns.

- Stay on Schedule Cleaning aligns with shift changes and peak activity windows so nothing disrupts your operations.

- Protect Your Reputation A spotless, well-maintained facility sends the right message to customers, inspectors, and partners.

- No Missed Spots, No Missed Shifts SmartClean ensures every area gets attention even third-shift work isn’t overlooked.

Entrainment & Public Venues

- Deliver a Spotless Guest Experience High-traffic areas stay clean and safe, giving visitors confidence from the moment they arrive.

- Protect Food & Safety Standards Automated documentation ensures food service and concession areas meet compliance every time.

- Keep Events Running Smoothly Cleaning aligns with showtimes, crowd flow, and peak usage without disrupting guest experience.

- Safeguard Your Reputation & Assets Proactive cleaning prevents costly complaints, liabilities, and damage to your brand.

Why Facility Leaders Choose Millennium SmartClean

Operational Efficiency

Stop wasting money on overstaffing or missed cleanings. SmartClean’s data-driven approach makes sure the right people are in the right place at the right time, reducing costs while improving results.

Complete Transparency

No more guessing if cleaning actually happened. SmartClean gives you clear, verifiable proof of every completed task — so you always know your facility is safe and ready.

Proactive Risk Management

Don’t wait for accidents, complaints, or compliance issues to strike. SmartClean spots risks early and keeps small problems from turning into costly disruptions.

Simplified Compliance

Forget scrambling for paperwork. Automated records show proof of due diligence and compliance — ready whenever inspectors, auditors, or leadership ask.

Resource Optimization

Your teams shouldn’t waste time on empty rooms while high-traffic areas are neglected. SmartClean directs resources where they’re needed most, maximizing impact without extra labor.

Continuous Improvement

Your facility shouldn’t stay stuck in yesterday’s routines. With ongoing analytics, SmartClean reveals ways to cut costs, improve safety, and keep operations running smoother every day.

Moving Beyond the Yellow Mop Bucket

Traditional facility maintenance is reactive, outdated, and costly. The “yellow mop bucket” approach no longer meets the demands of today’s fast-paced, compliance-driven industries.

Millennium SmartClean transforms facility maintenance from a necessary cost into a strategic advantage helping you protect people, extend asset life, and reduce operational costs with proven technology and processes.

Take the Next Step Toward Data-Driven Facility Excellence

Ready to transform how your industrial facility operates?

Frequently Asked Questions

Q: How long does it take to implement SmartClean in an industrial facility?

A: Typical implementation takes 14-21 days from initial assessment to full deployment, with minimal disruption to your operations.

Q: Does SmartClean require special IT infrastructure or WiFi coverage throughout the facility?

A: No. Our Verizon-powered system operates independently of your existing IT infrastructure, making it ideal for large industrial spaces with limited connectivity.

Q: How does SmartClean integrate with our existing maintenance management system?

A: SmartClean connects with over 300 business applications through standard APIs, allowing seamless integration with most CMMS, EAM, and ERP systems.

Q: Can SmartClean be customized for our specific industrial processes and compliance requirements?

A: Absolutely. We configure SmartClean to match your specific operations, including custom compliance documentation, specialized cleaning protocols, and integration with production schedules.

Q: How do we measure ROI from the SmartClean implementation?

A: The system provides detailed analytics on resource optimization, labor efficiency, supply usage, and maintenance effectiveness—all quantifiable factors that demonstrate clear return on investment.